What Is Tower Engineering?

Tower engineering is a specialized branch of structural engineering focused on the design, analysis, detailing, fabrication, and lifecycle management of tall, slender tower structures. These structures are widely used in power transmission, telecommunication, wind energy, lighting, and observation infrastructure.

Unlike conventional buildings, tower engineering is governed by:

-

Extreme height-to-base ratios

-

Wind-dominated loading conditions

-

Slender members sensitive to buckling

-

Highly connection-driven structural behavior

In real-world projects, even small detailing or connection errors can lead to fabrication rework, erection delays, or long-term serviceability issues. This is why tower engineering is treated as a system discipline, not just a modeling task.

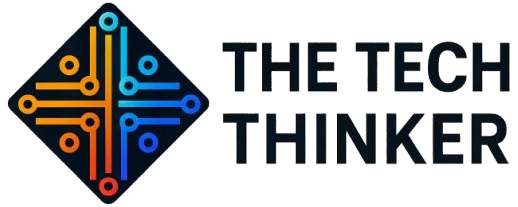

Why Tower Engineering Structurally Challenging

Tower structures behave very differently from typical steel frames or buildings.

Key challenges engineers face:

-

Wind governs design more than gravity loads

-

Slender members fail by buckling rather than yielding

-

Connections control performance, not member strength alone

-

Fabrication tolerances significantly affect final geometry

-

Erection sequence influences stress redistribution

In practice, tower engineering requires engineers to think beyond analysis results and consider fabrication, transport, erection, and long-term behavior from day one.

Types of Towers in Tower Engineering

Understanding tower types is fundamental to correct design decisions. Each type exists because it solves a specific engineering problem.

Types of Steel Towers – Comparison Table

| Tower Type | Basic Concept | Where Commonly Used | Key Structural Characteristics | Main Engineering Considerations |

|---|---|---|---|---|

| Lattice Tower | Open steel framework made of interconnected angle or tubular members | Power transmission lines, telecom networks, radar installations | High stiffness-to-weight ratio, good wind permeability, redundant load paths | Member buckling control, bracing continuity, connection detailing accuracy |

| Transmission Tower | Specialized lattice structure designed to carry electrical conductors | High-voltage and extra-high-voltage power lines | Supports conductor tension, vertical and transverse loads | Wind + conductor load combinations, electrical clearances, line deviation forces |

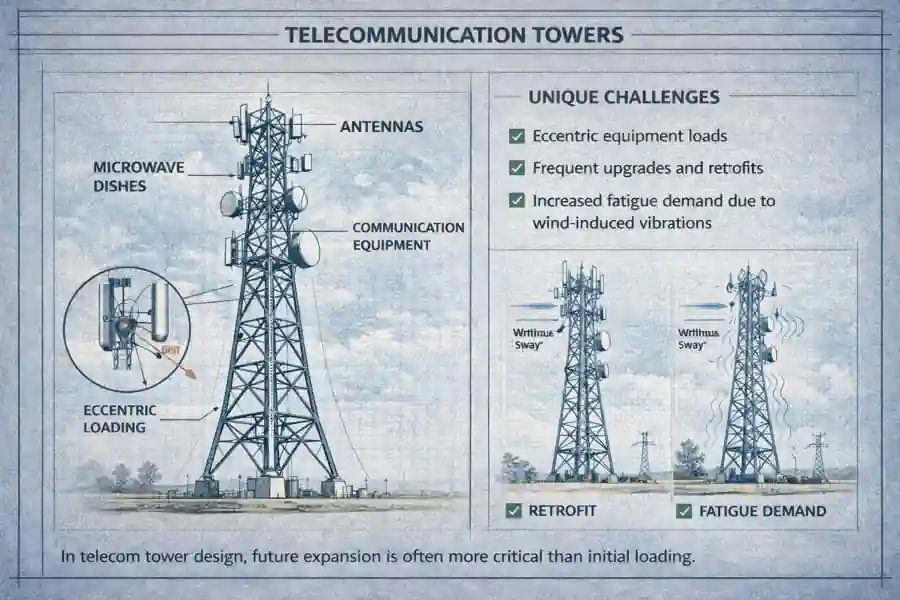

| Telecommunication Tower | Structure supporting antennas, dishes, and communication equipment | Mobile networks, microwave links, broadcast towers | Eccentric equipment loads, frequent upgrades | Fatigue due to wind, future loading provisions, vibration control |

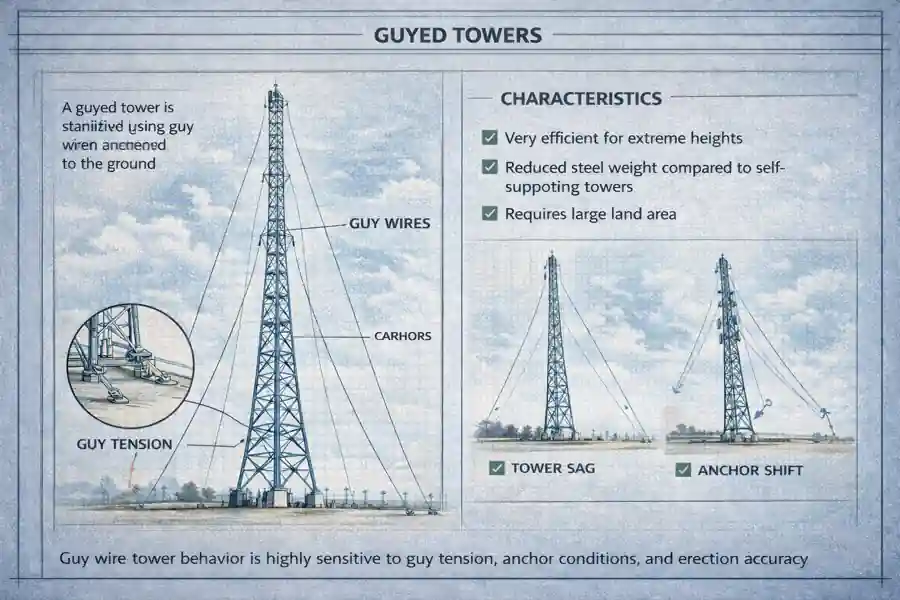

| Guyed Tower | Slender mast stabilized by tensioned guy wires | Very tall telecom masts, broadcast towers | Minimal steel weight, relies on guy anchors | Guy tension control, anchor design, erection sequencing |

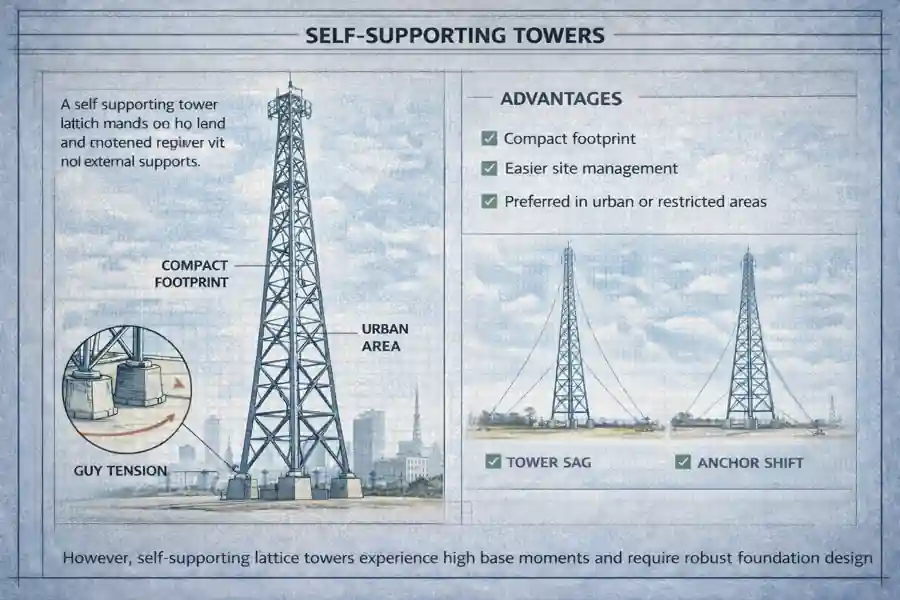

| Self-Supporting Tower | Free-standing structure without external supports | Urban telecom sites, restricted land areas | High base moments, compact footprint | Foundation design, overturning stability, erection constraints |

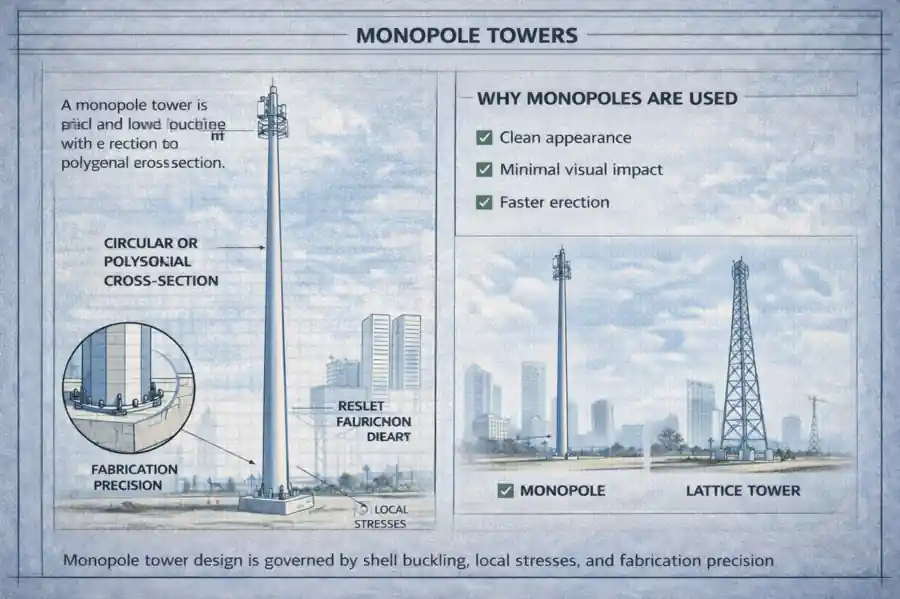

| Monopole Tower | Tubular steel pole (circular or polygonal section) | Urban telecom sites, highways, aesthetic zones | Smooth profile, limited internal access | Shell buckling, local stresses, fabrication precision |

| Wind Turbine Tower | Tall tubular structure supporting turbine nacelle and rotor | Wind farms, renewable energy projects | Subjected to cyclic loads and fatigue | Dynamic analysis, fatigue life, transport limitations |

| Lighting Tower | Tall mast supporting floodlights or high-mast lighting | Highways, stadiums, ports, industrial yards | Concentrated top loads, slender geometry | Deflection limits, vibration, maintenance access |

| Observation / Radar Tower | Tower supporting observation decks or radar equipment | Airports, defense, research facilities | Customized geometry, sensitive equipment loads | Precision alignment, serviceability, structural damping |

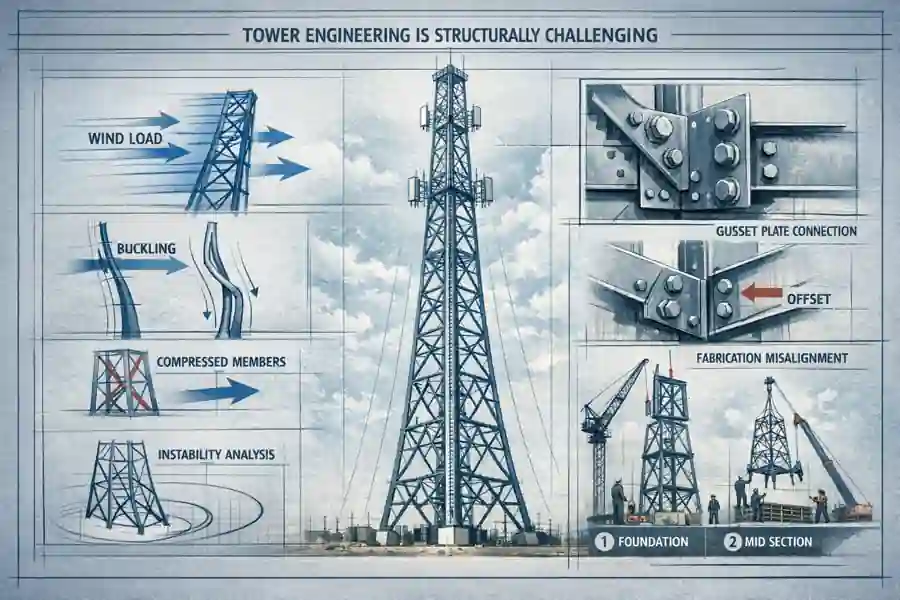

Lattice Towers

A lattice tower is composed of interconnected steel members forming a truss-like open framework.

Why lattice towers are used

-

Excellent wind permeability

-

High stiffness-to-weight ratio

-

Efficient load redistribution

Typical applications

-

Power transmission towers

-

Telecommunication towers

-

Radar and observation towers

Lattice tower design relies heavily on member orientation, bracing continuity, and connection consistency. Errors in these areas often surface only during fabrication or erection.

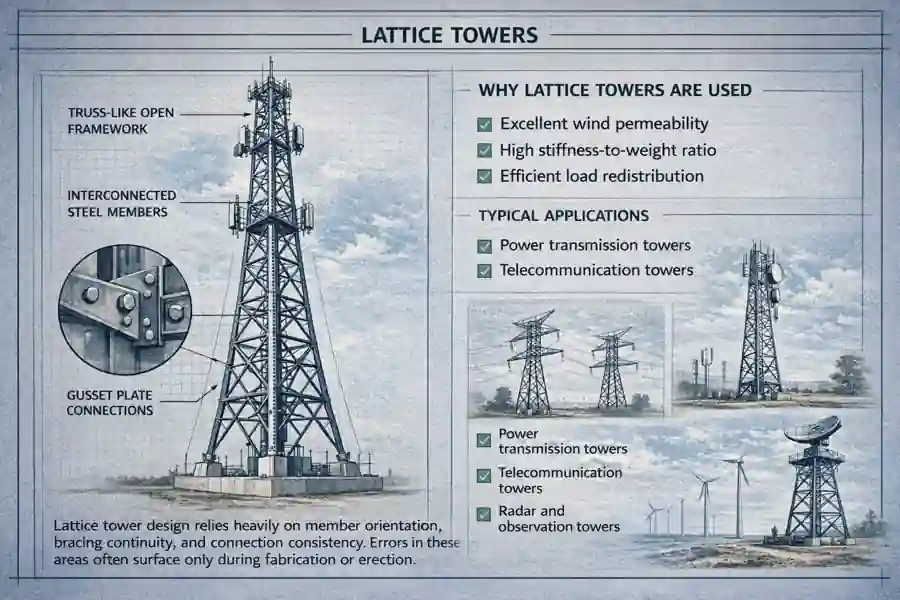

Transmission Towers

A transmission tower is specifically designed to carry electrical conductors and insulators over long spans.

Key design drivers

-

Wind load combined with conductor tension

-

Longitudinal and transverse load cases

-

Insulator swing and clearance requirements

Transmission line tower design demands strict adherence to standards and extremely accurate detailing, as minor dimensional errors can affect line geometry over kilometers.

Telecommunication Towers

A telecommunication tower supports antennas, microwave dishes, and communication equipment.

Unique challenges

-

Eccentric equipment loads

-

Frequent upgrades and retrofits

-

Increased fatigue demand due to wind-induced vibrations

In telecom tower design, future expansion is often more critical than initial loading.

Guyed Towers

A guyed tower is stabilized using guy wires anchored to the ground.

Characteristics

-

Very efficient for extreme heights

-

Reduced steel weight compared to self-supporting towers

-

Requires large land area

Guy wire tower behavior is highly sensitive to guy tension, anchor conditions, and erection accuracy.

Self-Supporting Towers

A self-supporting tower relies entirely on its base and structural system without external supports.

Advantages

-

Compact footprint

-

Easier site management

-

Preferred in urban or restricted areas

However, self-supporting lattice towers experience high base moments and require robust foundation design.

Monopole Towers

A monopole tower is a tubular steel structure with a circular or polygonal cross-section.

Why monopoles are used

-

Clean appearance

-

Minimal visual impact

-

Faster erection

Monopole tower design is governed by shell buckling, local stresses, and fabrication precision.

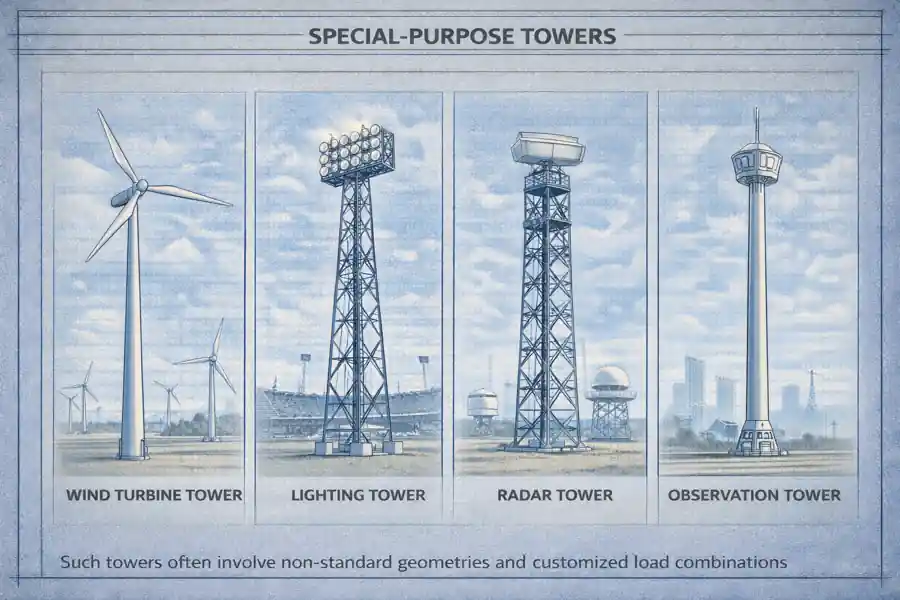

Special-Purpose Towers

These include:

-

Wind turbine towers

-

Lighting towers

-

Radar towers

-

Observation towers

Such towers often involve non-standard geometries and customized load combinations.

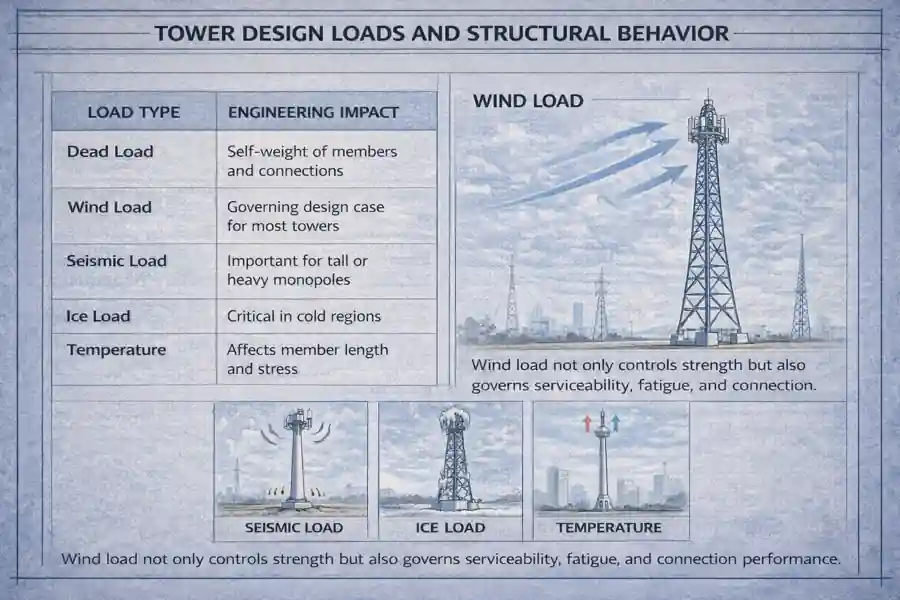

Tower Design Loads and Structural Behavior

Tower design loads differ from conventional structures.

| Load Type | Engineering Impact |

|---|---|

| Dead Load | Self-weight of members and connections |

| Wind Load | Governing design case for most towers |

| Seismic Load | Important for tall or heavy monopoles |

| Ice Load | Critical in cold regions |

| Temperature | Affects member length and stress |

Wind load not only controls strength but also governs serviceability, fatigue, and connection performance.

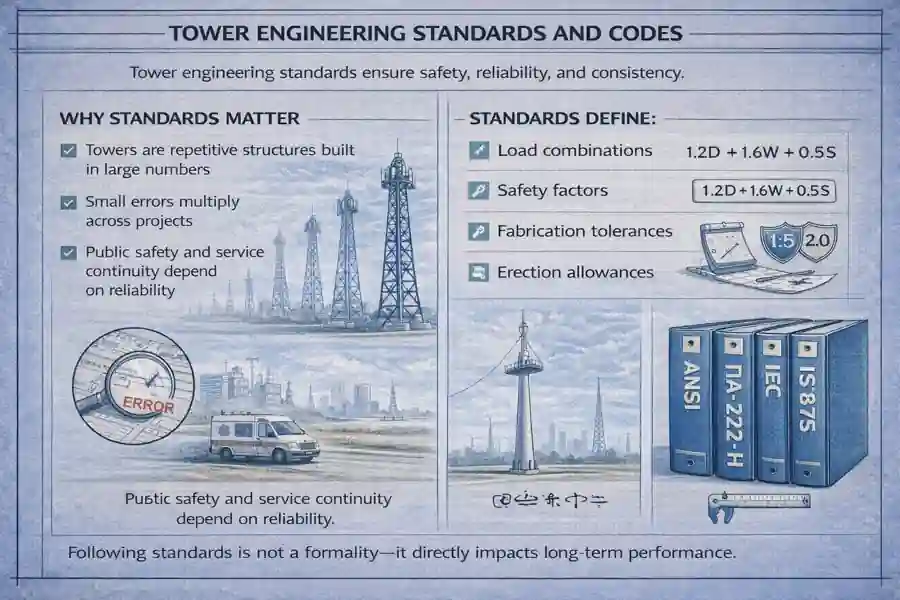

Tower Engineering Standards and Codes

Tower engineering standards ensure safety, reliability, and consistency.

Why standards matter

-

Towers are repetitive structures built in large numbers

-

Small errors multiply across projects

-

Public safety and service continuity depend on reliability

Standards define:

-

Load combinations

-

Safety factors

-

Fabrication tolerances

-

Erection allowances

Following standards is not a formality—it directly impacts long-term performance.

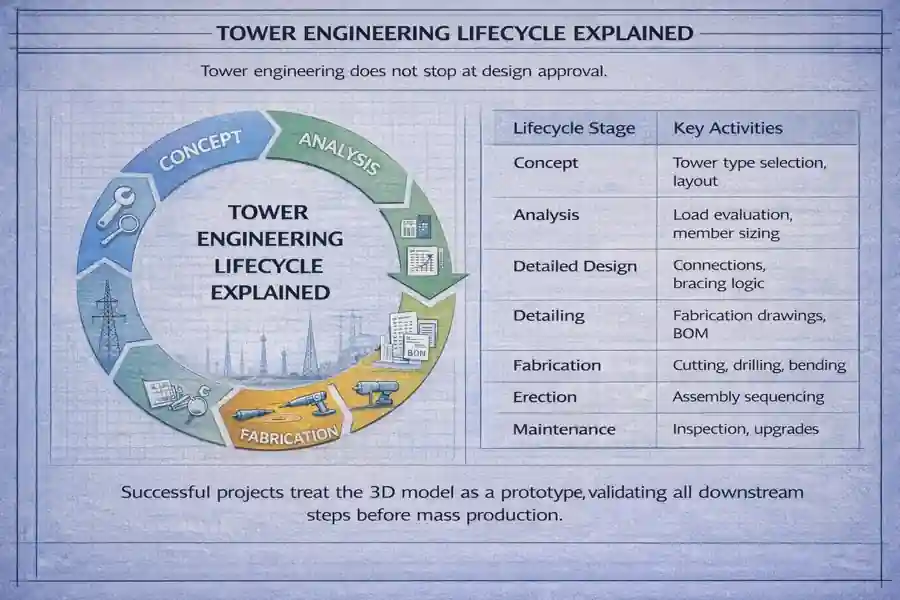

Tower Engineering Lifecycle Explained

Tower engineering does not stop at design approval.

| Lifecycle Stage | Key Activities |

|---|---|

| Concept | Tower type selection, layout |

| Analysis | Load evaluation, member sizing |

| Detailed Design | Connections, bracing logic |

| Detailing | Fabrication drawings, BOM |

| Fabrication | Cutting, drilling, bending |

| Erection | Assembly sequencing |

| Maintenance | Inspection, upgrades |

Successful projects treat the 3D model as a prototype, validating all downstream steps before mass production.

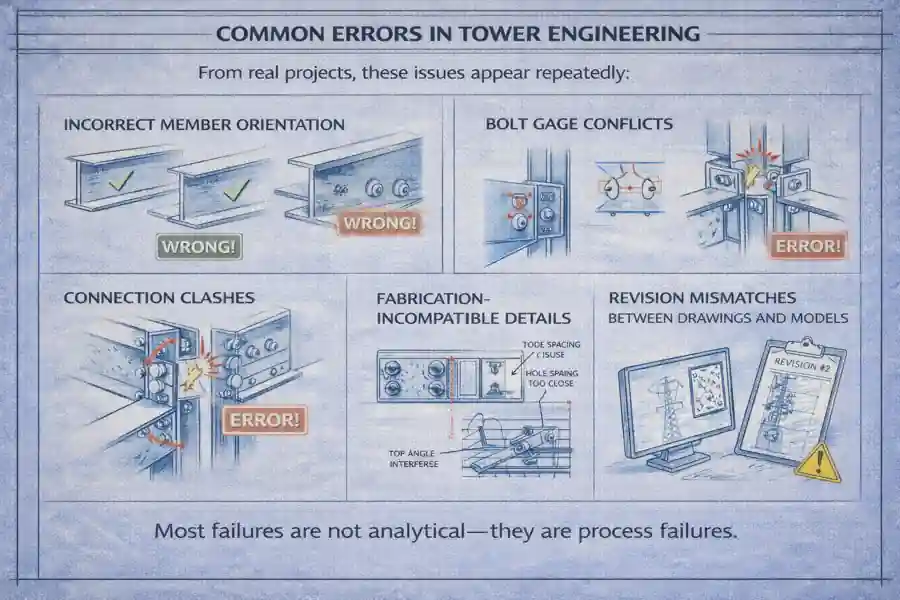

Common Errors in Tower Engineering

From real projects, these issues appear repeatedly:

-

Incorrect member orientation

-

Bolt gage conflicts

-

Connection clashes

-

Fabrication-incompatible details

-

Revision mismatches between drawings and models

Most failures are not analytical—they are process failures.

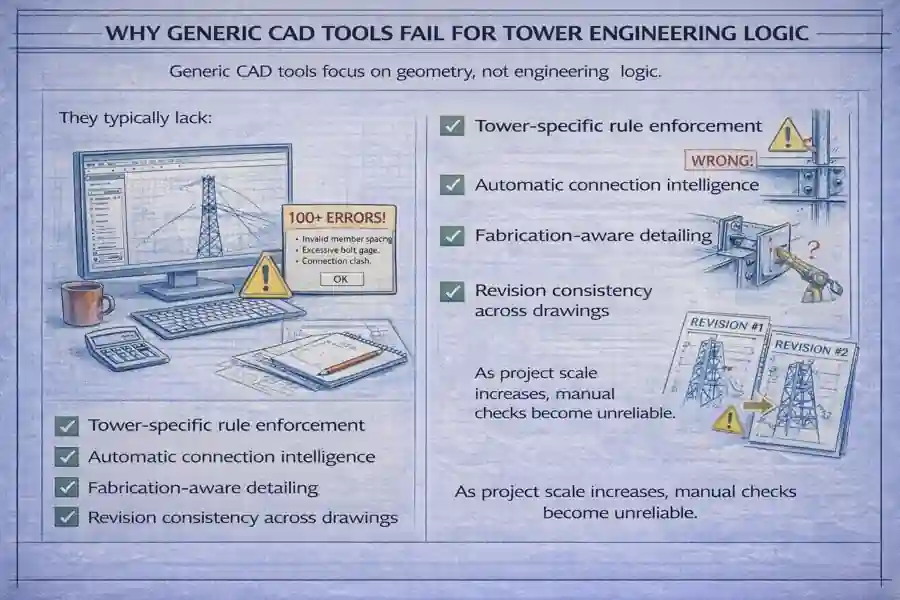

Why Generic CAD Tools Fail for Tower Engineering

Generic CAD tools focus on geometry, not engineering logic.

They typically lack:

-

Tower-specific rule enforcement

-

Automatic connection intelligence

-

Fabrication-aware detailing

-

Revision consistency across drawings

As project scale increases, manual checks become unreliable.

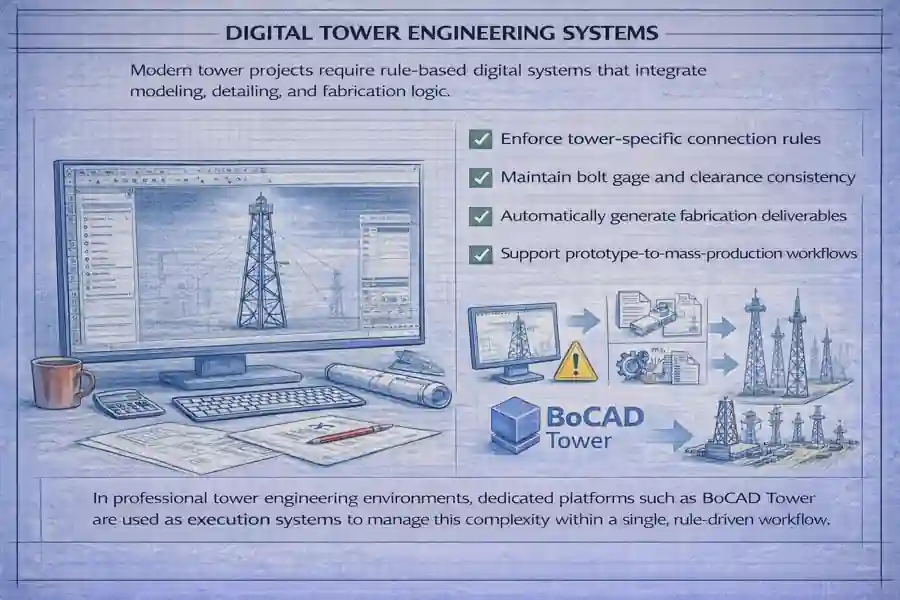

Digital Tower Engineering Systems

Modern tower projects require rule-based digital systems that integrate modeling, detailing, and fabrication logic.

These systems:

-

Enforce tower-specific connection rules

-

Maintain bolt gage and clearance consistency

-

Automatically generate fabrication deliverables

-

Support prototype-to-mass-production workflows

In professional tower engineering environments, dedicated platforms such as BoCAD Tower are used as execution systems to manage this complexity within a single, rule-driven workflow.

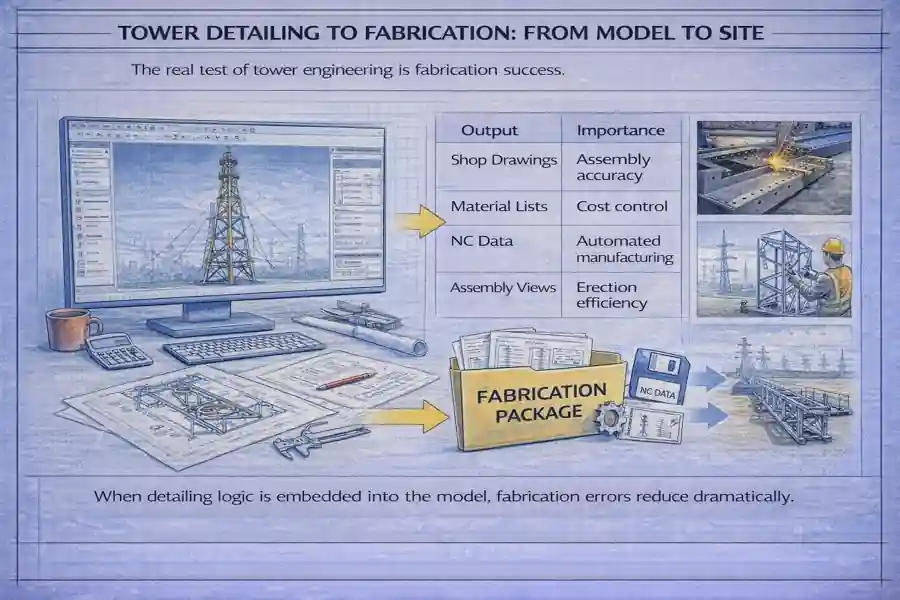

Tower Detailing to Fabrication: From Model to Site

The real test of tower engineering is fabrication success.

| Output | Importance |

|---|---|

| Shop Drawings | Assembly accuracy |

| Material Lists | Cost control |

| NC Data | Automated manufacturing |

| Assembly Views | Erection efficiency |

When detailing logic is embedded into the model, fabrication errors reduce dramatically.

Future of Tower Engineering

Tower engineering continues to evolve toward:

-

Automation-driven detailing(Started happening now in 2025)

-

Digital twins

-

AI-assisted validation

-

Sustainability-focused optimization

However, the fundamentals—loads, behavior, connections, and lifecycle thinking—remain unchanged.

Conclusion:

Tower engineering is not just about designing tall structures.

It is about coordinating analysis, detailing, fabrication, and erection as a single system.

Engineers who understand this system-level discipline consistently deliver safer, faster, and more reliable tower projects—regardless of software trends or technology shifts.

Related Articles

External Reference

- American Society of Civil Engineers

- International Electrotechnical Commission (IEC)

- American Institute of Steel Construction

Tower Engineering- FAQ

1. What makes tower structures different from regular buildings?

Tower structures are designed primarily to resist environmental forces rather than occupancy loads. Their height, slenderness, and exposure make their behavior fundamentally different from conventional buildings.

-

Wind governs most design decisions

-

Buckling controls member sizing

-

Connections influence global stability

-

Fabrication accuracy directly affects performance

2. Why are lattice towers widely used in infrastructure projects?

Lattice towers offer an efficient balance between strength, stiffness, and material usage. Their open framework allows wind to pass through, reducing overall force demand.

-

High stiffness-to-weight ratio

-

Reduced wind pressure

-

Easy inspection and maintenance

-

Suitable for repetitive mass production

3. How does transmission line tower design differ from telecom towers?

Transmission line towers are governed by conductor forces and electrical clearances, while telecom towers are dominated by equipment loads and future expansion needs.

-

Conductor tension affects load cases

-

Electrical safety clearances are critical

-

Telecom towers face frequent retrofits

-

Load eccentricity is more common in telecom

4. What are the main load cases considered in tower structures?

Tower structures are subjected to a combination of environmental and operational loads that vary by location and function.

-

Wind load (primary governing case)

-

Dead weight of steel and equipment

-

Seismic effects in active zones

-

Ice and temperature effects in cold regions

5. Why do wind loads dominate tall tower design?

Wind pressure increases with height and directly impacts both strength and serviceability of tall, slender structures.

-

Height amplifies wind speed

-

Slender members attract dynamic effects

-

Fatigue becomes a design concern

-

Connection forces increase significantly

6. What is a guyed tower and when is it preferred?

A guyed tower is stabilized using tensioned cables anchored to the ground, making it efficient for very tall installations.

-

Requires less steel than freestanding towers

-

Suitable for extreme heights

-

Needs large land area for anchors

-

Guy tension control is critical

7. How does a self-supporting tower achieve stability?

Self-supporting towers rely entirely on their structural frame and foundation to resist loads without external support.

-

High base moment resistance

-

Compact footprint

-

Preferred in restricted sites

-

Foundation design is critical

8. Why are monopole towers common in urban environments?

Monopole towers offer a clean appearance and require less space, making them suitable for cities and highways.

-

Minimal visual impact

-

Faster erection time

-

Reduced land requirement

-

Controlled access for maintenance

9. What role do connections play in tower stability?

Connections often govern structural behavior more than members themselves in tower structures.

-

Control load transfer paths

-

Influence global stiffness

-

Sensitive to fabrication tolerances

-

Critical during erection stages

10. Why are fabrication tolerances critical in tower projects?

Small dimensional errors can accumulate across multiple components, leading to erection difficulties.

-

Misalignment issues on site

-

Bolt fit-up problems

-

Increased rework costs

-

Schedule delays during erection

11. What is meant by prototype-based tower detailing?

Prototype-based detailing treats a single tower model as the reference for repeated fabrication.

-

Ensures consistency across towers

-

Reduces detailing errors

-

Simplifies quality control

-

Supports mass production

12. Why do generic CAD tools struggle with tower projects?

General drafting tools lack the engineering intelligence required for complex tower geometries.

-

No rule-based connection logic

-

Manual consistency checks required

-

Limited fabrication awareness

-

Poor revision control

13. How does digital detailing improve tower fabrication?

Digital detailing systems integrate design intent directly into fabrication outputs.

-

Automated shop drawings

-

Accurate material quantities

-

Reduced manual interpretation

-

Faster production cycles

14. What challenges arise during tower erection?

Erection is often the most sensitive stage of a tower project.

-

Sequence affects stress redistribution

-

Temporary instability risks

-

Alignment tolerance issues

-

Safety constraints on site

15. Why is lifecycle thinking important in tower projects?

Tower structures often remain in service for decades and undergo multiple modifications.

-

Future equipment upgrades

-

Long-term maintenance planning

-

Structural health monitoring

-

Adaptability to changing loads

16. How do standards influence tower safety?

Design standards provide consistency, safety margins, and reliability across projects.

-

Define load combinations

-

Specify safety factors

-

Control detailing practices

-

Ensure regulatory compliance

17. What causes most failures in tower projects?

Most issues arise from process gaps rather than incorrect calculations.

-

Inconsistent detailing

-

Poor coordination between teams

-

Fabrication mismatches

-

Uncontrolled revisions

18. How are wind turbine towers structurally different?

Wind turbine towers are subjected to continuous cyclic loading due to rotating machinery.

-

High fatigue demand

-

Dynamic load amplification

-

Transport limitations

-

Strict alignment requirements

19. Why is revision control critical in large tower programs?

Tower projects often involve hundreds or thousands of similar units.

-

Small changes propagate widely

-

Drawing mismatches cause errors

-

Fabrication delays increase costs

-

Site confusion during erection

20. What skills are essential for engineers working on tower projects?

Tower projects demand both analytical strength and practical understanding.

-

Structural analysis expertise

-

Detailing and fabrication awareness

-

Standards and code knowledge

-

Coordination across disciplines

21. What types of towers are typically handled in tower engineering software?

In professional tower engineering, software platforms are expected to handle a wide range of tower configurations used across infrastructure projects. Dedicated systems such as BoCAD Tower are designed specifically for this diversity.

-

Lattice towers used in power transmission networks

-

Transmission line towers with conductor and insulator loads

-

Telecommunication towers supporting antennas and dishes

-

Guyed, self-supporting, and monopole tower structures

22. What software is used in real-world tower engineering projects?

Modern tower engineering projects rely on specialized tools rather than generic CAD software, especially when fabrication accuracy and repetition are critical. Industry workflows commonly include BoCAD Tower and SC BoCAD for execution-level detailing.

-

Structural analysis tools for load calculations

-

BoCAD Tower for rule-based tower modeling and detailing

-

SC BoCAD for steel construction and fabrication workflows

-

Integrated systems for drawings, quantities, and NC data

23. Why is BoCAD Tower widely used for tower engineering and detailing?

In tower engineering, BoCAD Tower is recognized for addressing practical challenges that arise during detailing and fabrication of lattice and transmission towers.

-

Built specifically for tower and lattice structures

-

Rule-based connection and bracing logic

-

Consistent bolt gage and clearance control

-

Fabrication-ready outputs for large tower programs

24. Is SC BoCAD considered an industry-standard platform for tower projects?

Across large-scale tower engineering programs, SC BoCAD is often treated as an industry-standard solution due to its maturity and focus on steel construction workflows.

-

Proven use in power transmission and telecom projects

-

Strong integration between modeling and fabrication

-

Supports repetitive tower structures efficiently

-

Suitable for prototype-to-mass-production environments

25. How do BoCAD Tower improve tower engineering outcomes?

Using dedicated platforms like BoCAD Tower improves reliability and efficiency in tower engineering, particularly when projects involve hundreds of similar structures.

-

Reduced detailing and fabrication errors

-

Improved consistency across tower families

-

Faster drawing and quantity generation

-

Better coordination between design, fabrication, and site teams