Introduction

Digital Twin is no longer a futuristic buzzword or a marketing phrase used by enterprise vendors. Today, this concept has become a practical engineering and intelligence framework used to understand, monitor, predict, and optimize real-world systems across manufacturing, aerospace, infrastructure, energy, and healthcare.

Unlike traditional CAD models or offline simulations, this live system model is alive. It evolves with real-world data, reflects operational behavior, and supports informed decision-making throughout the lifecycle of a product, machine, or system.

This guide is intentionally written as a complete, end-to-end reference. It does not skim the surface. Instead, it walks you from foundational concepts to advanced architectural, data, AI, and governance considerations—the way such systems are actually built and used in industry today.

If you are an engineer, system architect, data professional, or technology decision-maker, this article is designed to give you clarity, depth, and practical understanding, not hype.

What Is a Digital Twin?

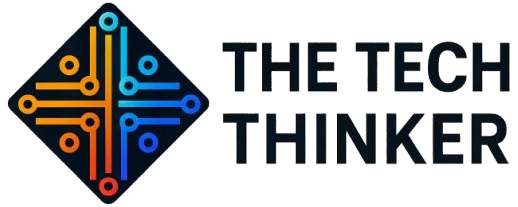

A Digital Twin is a dynamic, continuously updated digital representation of a physical asset, process, or system, connected through real-world data and capable of reflecting current state, historical behavior, and future outcomes.

At its core, this approach combines:

-

A physical entity (machine, product, system, or environment)

-

A digital representation (models, logic, and structure)

-

A data connection (sensors, logs, operational data)

-

A feedback loop for analysis, prediction, and optimization

What This System IS

-

A living system, not a static model

-

Data-driven and context-aware

-

Capable of prediction and optimization

-

Continuously evolving across the lifecycle

What This System Is NOT

-

Just a 3D CAD model

-

A one-time simulation study

-

A dashboard without intelligence

-

A disconnected digital replica

This connected model exists to answer engineering and operational questions in real time, not just to visualize geometry.

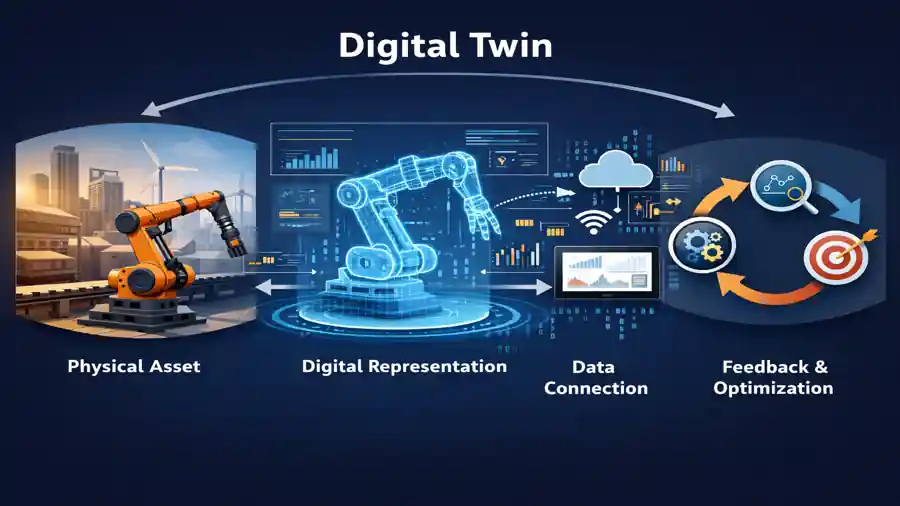

Why Digital Twin Is Trending in 2025

The rapid adoption of this technology in 2025 is not accidental. Multiple technology trends have converged to make such systems feasible, scalable, and valuable.

Key drivers include:

-

Mature IoT ecosystems enabling reliable data capture

-

Lower AI inference costs, making prediction affordable

-

Improved simulation and physics solvers

-

Cloud and edge computing maturity

-

System-level engineering focus replacing siloed tools

Industries are no longer asking “What is a Digital Twin?”

They are asking “How fast can we deploy one that delivers ROI?”

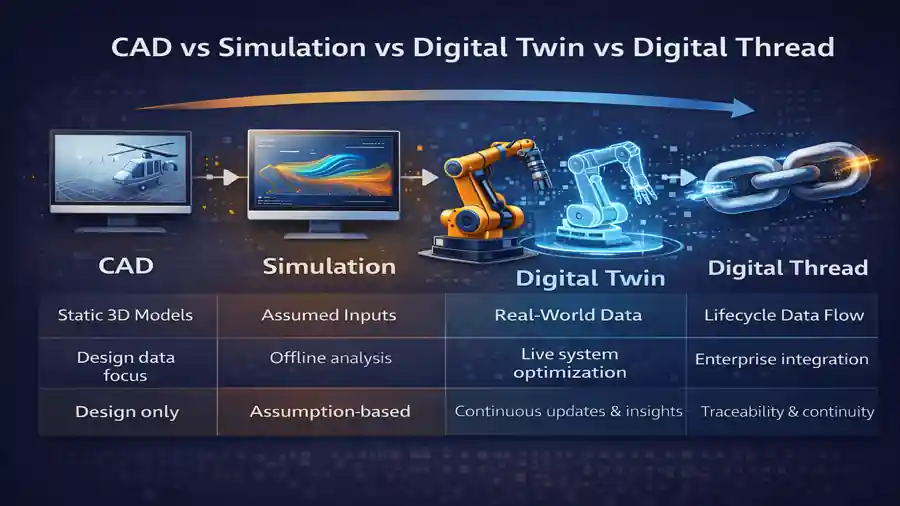

Digital Twin vs Simulation vs CAD vs Digital Thread

Understanding these differences is critical to avoiding confusion and failed implementations.

| Aspect | CAD | Simulation | Digital Twin | Digital Thread |

|---|---|---|---|---|

| Nature | Static | Scenario-based | Live & dynamic | Lifecycle data flow |

| Data Source | Design data | Assumed inputs | Real-world data | Enterprise systems |

| Time Behavior | Fixed | Offline | Continuous | Longitudinal |

| Intelligence | None | Limited | Predictive & prescriptive | Traceability |

| Purpose | Design | Analysis | Optimization | Continuity |

This system uses simulation, CAD, and Digital Thread concepts, but goes beyond all of them by closing the loop between physical and digital worlds.

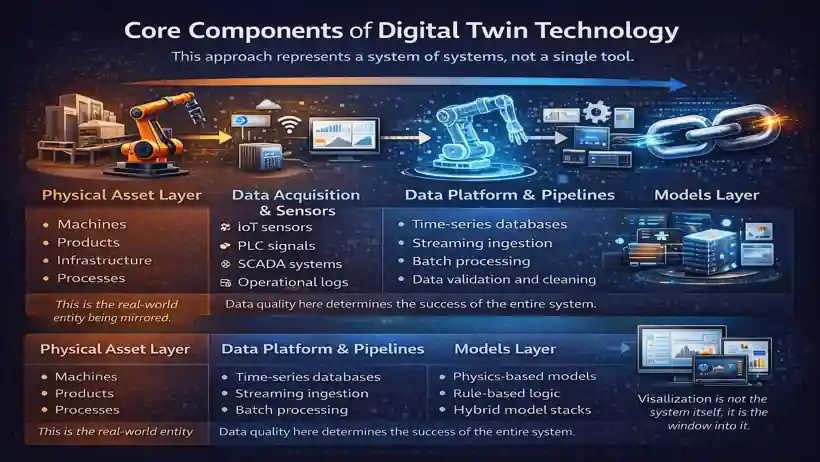

Core Components of Digital Twin Technology

This approach represents a system of systems, not a single tool.

Physical Asset Layer

-

Machines

-

Products

-

Infrastructure

-

Processes

This is the real-world entity being mirrored.

Data Acquisition & Sensors

-

IoT sensors

-

PLC signals

-

SCADA systems

-

Operational logs

-

Maintenance records

Data quality here determines the success of the entire system.

Data Platform & Pipelines

-

Time-series databases

-

Streaming ingestion

-

Batch processing

-

Data validation and cleaning

Most failures originate in this layer, not AI.

Models Layer

-

Physics-based models (FEM, CFD, kinematics)

-

Rule-based logic

-

Machine learning models

-

Hybrid model stacks

Visualization & Interaction

-

Dashboards

-

3D viewers

-

Analytics panels

-

Decision-support interfaces

Visualization is not the system itself; it is the window into it.

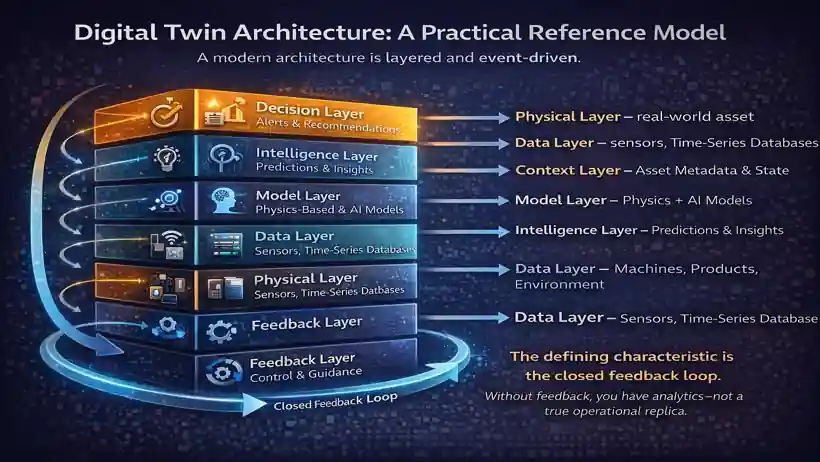

Digital Twin Architecture: A Practical Reference Model

A modern architecture is layered and event-driven.

Typical structure:

-

Physical Layer – real-world asset

-

Data Layer – sensor ingestion & storage

-

Context Layer – asset metadata & state

-

Model Layer – physics + AI

-

Intelligence Layer – predictions & insights

-

Decision Layer – alerts, recommendations

-

Feedback Layer – control or guidance

The defining characteristic is the closed feedback loop.

Without feedback, you have analytics—not a true operational replica.

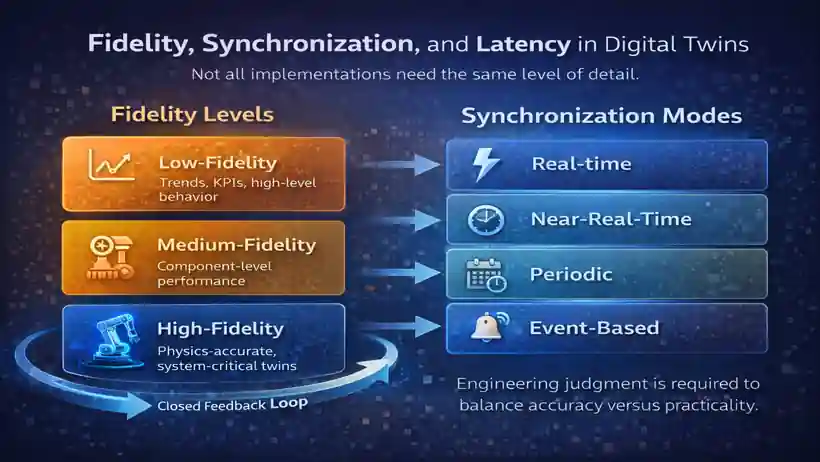

Fidelity, Synchronization, and Latency in Digital Twins

Not all implementations need the same level of detail.

Fidelity Levels

-

Low-fidelity: trends, KPIs, high-level behavior

-

Medium-fidelity: component-level performance

-

High-fidelity: physics-accurate, system-critical twins

Higher fidelity increases cost, complexity, and data demand.

Synchronization Modes

-

Real-time

-

Near-real-time

-

Periodic

-

Event-based

Engineering judgment is required to balance accuracy versus practicality.

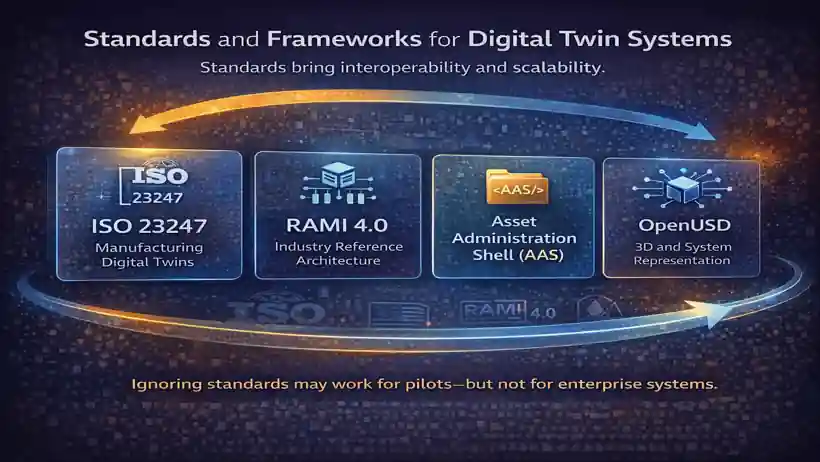

Standards and Frameworks for Digital Twin Systems

Standards bring interoperability and scalability.

Key frameworks include:

-

ISO 23247 – Manufacturing Digital Twins

-

RAMI 4.0 – Industry reference architecture

-

Asset Administration Shell (AAS)

-

OpenUSD for 3D and system representation

Ignoring standards may work for pilots—but not for enterprise systems.

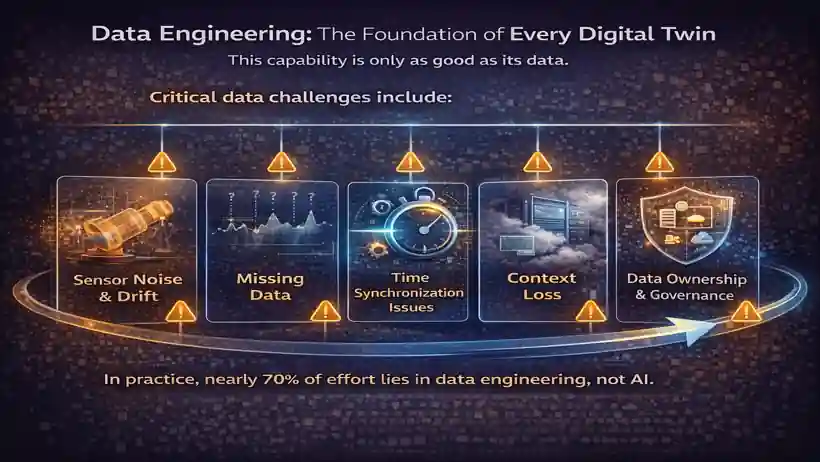

Data Engineering: The Foundation of Every Digital Twin

This capability is only as good as its data.

Critical data challenges include:

-

Sensor noise and drift

-

Missing data

-

Time synchronization issues

-

Context loss

-

Data ownership and governance

In practice, nearly 70% of effort lies in data engineering, not AI.

Physics-Based vs AI-Based Digital Twins

| Aspect | Physics-Based Twin | AI-Based Twin |

|---|---|---|

| Data dependency | Low | High |

| Interpretability | Very high | Medium |

| Adaptability | Limited | High |

| Computational cost | High | Variable |

| Failure prediction | Rule-based | Learned patterns |

Best Practice: Hybrid Digital Twins

Modern implementations combine:

-

Physics for known behavior

-

AI for unknown or emergent behavior

This hybrid approach delivers accuracy and adaptability.

Generative AI and Digital Twin: Reality vs Hype

Generative AI adds value when used correctly.

Valid use cases

-

Natural-language interaction with system data

-

Automated report generation

-

Design exploration

-

Decision explanation

Invalid use cases

-

Replacing physics models

-

Autonomous control without validation

-

Guessing system behavior

Generative AI should assist, not replace engineering judgment.

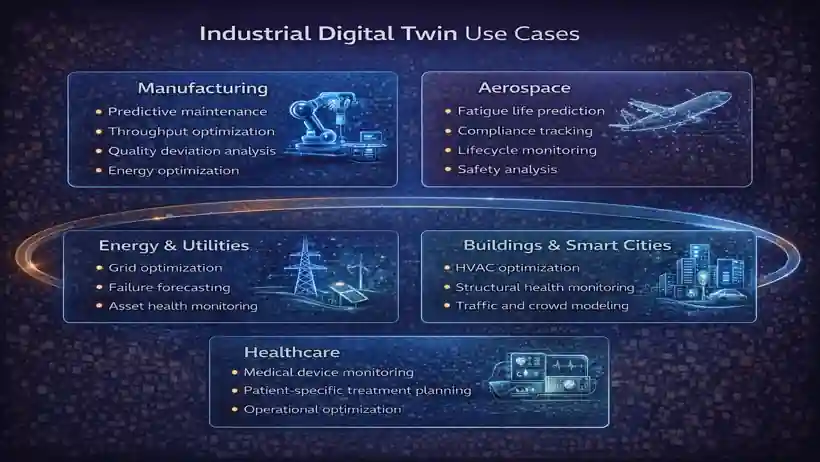

Industrial Digital Twin Use Cases

Manufacturing

-

Predictive maintenance

-

Throughput optimization

-

Quality deviation analysis

-

Energy optimization

Aerospace

-

Fatigue life prediction

-

Compliance tracking

-

Lifecycle monitoring

-

Safety analysis

Energy & Utilities

-

Grid optimization

-

Failure forecasting

-

Asset health monitoring

Buildings & Smart Cities

-

HVAC optimization

-

Structural health monitoring

-

Traffic and crowd modeling

Healthcare

-

Medical device monitoring

-

Patient-specific treatment planning

-

Operational optimization

Digital Twin Platforms and Tools Landscape

Solutions in this space fall into categories:

-

Industrial platforms

-

Simulation-centric systems

-

AI-centric platforms

-

Open-source component stacks

No single tool builds a complete system.

Architecture matters more than brand.

Step-by-Step Digital Twin Implementation Roadmap

-

Define the problem clearly

-

Identify measurable outcomes

-

Select appropriate fidelity

-

Validate data readiness

-

Build an MVP

-

Validate against real outcomes

-

Scale responsibly

-

Establish ownership and governance

These systems should grow with value, not ambition.

Common Digital Twin Failures (and How to Avoid Them)

-

Over-modeling without purpose

-

Poor data quality

-

Unrealistic expectations

-

Lack of ownership

-

Treating the system as a project, not a capability

Successful teams treat this as a long-term investment.

Security, Governance, and Ethics of Digital Twins

Key concerns include:

-

Data security

-

IP protection

-

Safety-critical decisions

-

AI bias

-

Regulatory compliance

Such implementations can become a single source of truth—or a single point of failure.

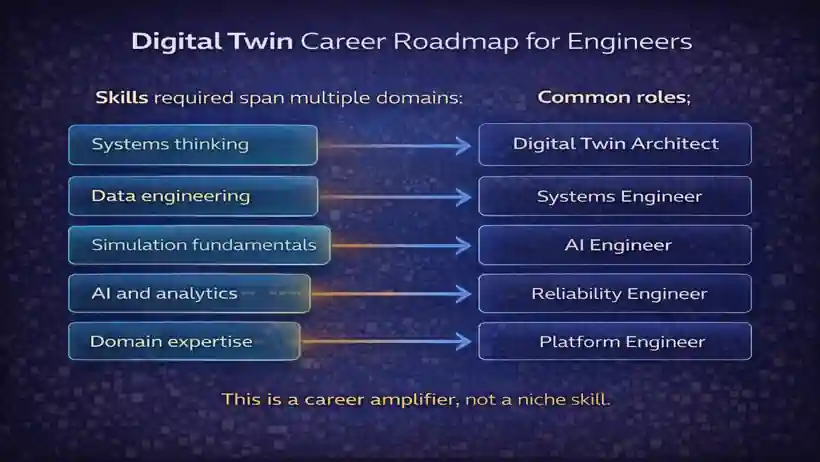

Digital Twin Career Roadmap for Engineers

Skills required span multiple domains:

-

Systems thinking

-

Simulation fundamentals

-

AI and analytics

-

Domain expertise

Common roles include:

-

Digital Twin Architect

-

Systems Engineer

-

AI Engineer

-

Reliability Engineer

-

Platform Engineer

This is a career amplifier, not a niche skill.

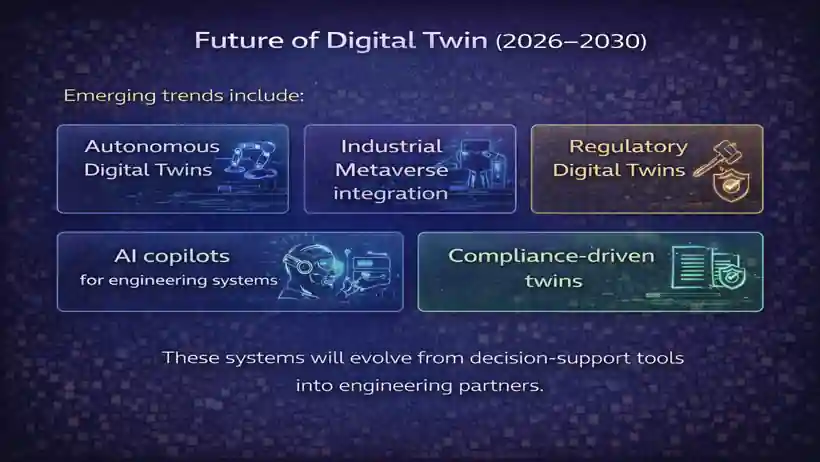

Future of Digital Twin (2026–2030)

Emerging trends include:

-

Autonomous Digital Twins

-

Industrial Metaverse integration

-

Regulatory Digital Twins

-

AI copilots for engineering systems

-

Compliance-driven twins

These systems will evolve from decision-support tools into engineering partners.

Conclusion

Digital Twin is not a tool—it is a new way of thinking about systems.

It merges engineering, data, and intelligence into a unified, evolving representation of reality.

Organizations that understand this approach deeply will design safer systems, make better decisions, and move faster with confidence.

For engineers and technologists, mastering these concepts today is an investment in long-term relevance and leadership.

Related Articles

External Reference

- ISO 23247 – Digital Twin Framework overview

- Predictive Maintenance with Twin-enabled Systems

- Detailed Technology Definition from AWS

Frequently Asked Questions (FAQs)

1. What is a Digital Twin used for in real-world engineering?

It is used to monitor live system behavior, analyze performance trends, predict potential failures, and support better operational and design decisions across the lifecycle.

2. How does a Digital-Twin System differ from traditional simulation tools?

Traditional simulations are usually offline and scenario-based, while this approach connects models with operational data to reflect current and evolving system conditions.

3. Is a Digital Twin always connected to real-time data?

Not necessarily. Many implementations rely on near-real-time or event-based updates, depending on business goals, system criticality, and data availability.

4. Can a Digital Twin work without artificial intelligence?

Yes. Physics-based models and rule-driven logic can deliver value on their own, while AI enhances prediction, pattern detection, and optimization when data maturity allows.

5. What industries benefit the most from Digital-Twin adoption?

Manufacturing, aerospace, energy, infrastructure, healthcare, and smart buildings see strong benefits due to complex assets, high downtime costs, and safety requirements.

6. How complex does a Digital-Twin need to be at the start?

It does not need to be complex. Many successful initiatives begin with a focused scope, such as a single asset or process, and evolve gradually as value is proven.

7. What are the biggest challenges in building a Digital-Twin?

Common challenges include poor data quality, unclear objectives, integration complexity, and lack of ownership rather than limitations in software or computing power.

8. Does a Digital-Twin replace existing monitoring dashboards?

No. It builds on existing monitoring by adding context, models, and predictive insight, rather than replacing dashboards already used by operations teams.

9. How is success measured after deploying a Digital-Twin?

Success is measured through tangible outcomes such as reduced downtime, improved efficiency, better forecasting accuracy, and measurable cost or risk reduction.

10. What skills do engineers need to work effectively with Digital-Twin systems?

Strong systems thinking, domain knowledge, data understanding, and the ability to connect engineering models with operational realities are more important than specific tools.

11. How does a Digital Twin help in predictive maintenance?

It helps by analyzing historical and live operational data to identify patterns that indicate wear, degradation, or abnormal behavior before failures occur.

12. Can a Digital Twin be built without advanced sensors?

Yes. Even basic operational logs, manual inputs, or legacy system data can be used initially, though richer sensor data improves accuracy and depth over time.

13. How long does it take to implement a Digital Twin in practice?

Timelines vary widely. Small, focused implementations can be completed in weeks, while enterprise-wide systems may take several months or longer.

14. Is a Digital Twin useful during the design phase of a product?

Yes. It can be used to validate assumptions, compare design alternatives, and later carry design intent into manufacturing and operational phases.

15. How does a Digital Twin support decision-making for managers?

It provides context-rich insights, forecasts, and scenario evaluations that help leaders make informed decisions rather than relying only on static reports.

16. Can a Digital Twin operate in safety-critical environments?

Yes, but it must be carefully validated, governed, and restricted to advisory roles unless rigorous certification and safeguards are in place.

17. What data types are commonly used in a Digital Twin system?

Typical data includes time-series sensor readings, event logs, maintenance records, configuration data, and contextual metadata.

18. How does a Digital Twin scale across multiple assets or sites?

Scaling is achieved through standardized data models, reusable architectures, and centralized governance while allowing local variations where necessary.

19. Does a Digital Twin require constant manual intervention?

No. Once properly configured, most monitoring and analysis tasks run automatically, with human involvement focused on review and decision-making.

20. What is the long-term value of investing in a Digital Twin?

Long-term value comes from improved reliability, operational efficiency, knowledge retention, and the ability to adapt systems based on real evidence rather than assumptions.